[ad_1]

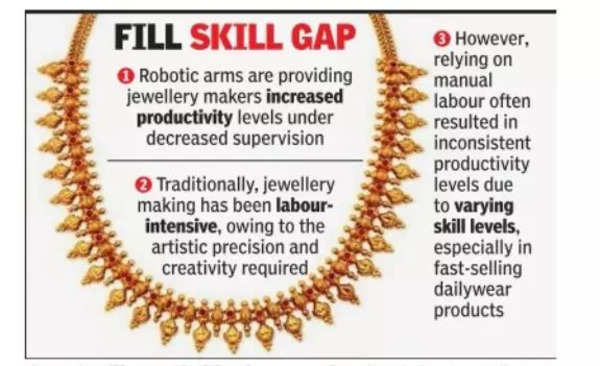

Jewelery manufacturers like Tanishq and Malabar Gold are integrating robotic arms into their studios, harnessing the machines’ agile motion and precision. From chain-making to sharpening to casting, these machines are offering jewellery makers elevated productiveness ranges below decreased supervision.

“Many of the automation programs run in a number of shifts and require lesser upkeep.They’ve enhanced productiveness greater than two occasions compared to standard strategies,” mentioned a Tanishq spokesperson, which launched robots into its jewellery-making course of in 2020 with an almost Rs 5-crore funding. At the moment , Tanishq’s manufacturing unit in Tamil Nadu’s Hosur is supplied with three robots.

Malabar Gold and Diamonds, too, has launched robots and automation programs in its manufacturing course of, serving to it remove guide duties and preserve uniform high quality in jewelery manufacturing, It carried out the method final yr with an almost Rs 30-crore funding.

“The automated programs are primarily utilized in chain-making and sharpening operations. Ancillary duties like cleansing and mould-handling have additionally been automated,” mentioned MP Ahammed, chairman of Malabar Gold & Diamonds.

Jewelery making has been labour-intensive historically, owing to the creative precision and creativity required for beautiful merchandise. Nonetheless, fast-selling dailywear merchandise like plain hoops, wedding ceremony bands, diamond engagement rings and bangles have exited the realm involving guide duties. Cash, which have emerged as a preferred funding choice, aside from being a handy gifting merchandise throughout festivals, too, are being made with retrofitted machines.

“Beforehand, counting on guide labor usually resulted in inconsistent productiveness ranges on account of various talent ranges and the inherent limitations of guide operations. Nonetheless, automation has ensured error-free processes, doubling our productiveness and sustaining a constant, fantastic uniform high quality throughout merchandise, ” mentioned Ahmed.

At Tanishq, greater than 150 workers work together with a crew of 30-plus know-how consultants within the machine-made jewelery part.

The Indian jewelery sector is in for extra competitors with the Aditya Birla Group planning a foray into the area. It might have a look at automated jewellery manufacturing as effectively.

The Indian jewelery market is valued at Rs 8 lakh crore and is anticipated to develop on the charge of 5-7% yearly.

Globally, too, luxurious manufacturers like Bulgari and Christian Tse have began utilizing automation programs to make fundamental jewelery items.

Whereas gold costs proceed to be dictated upward by international elements, manufacturing prices for jewelers switching to automation programs have resulted in prices dropping by 50% as towards the traditional methodology.

[ad_2]

2024-04-01 01:58:03

[

+ There are no comments

Add yours